Understanding the Power Behind Modern Transformers — Parts of a Transformer

Transformers quietly sit at the heart of our power systems, humming away, doing thier job every single day without much applause. Yet inside these metal giants lies a mix of engineering, material science and craftsmanship. In this article, we take a deeper walk into the world of transformer construction — especially the critical insulation components — and why companies like KE Core Electric have grown into trusted partners across the industry.

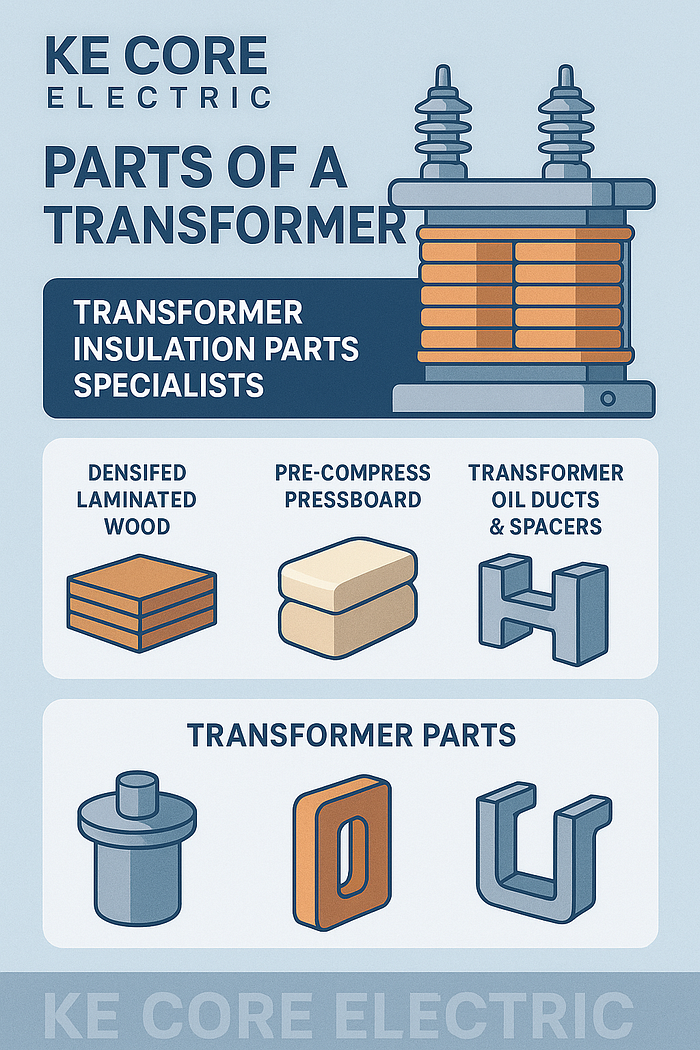

While many people know only the basic Parts of a Transformer, very few stop to think how insulation, structure and high-performance materials keep everything safe. The unsung heroes are often the ones designing and delivering these specialized components, including Transformer Insulation Parts Specialists who make sure reliability never slips.

Why Transformer Insulation Still Matters More Than Ever

Even with huge advances in power technology, transformer insulation remains the first and last line of defence. Every electrical surge, temperature spike or short-term overload hits the insulation system before anything else.

And that’s where the expertise of KE CORE ELECTRIC PRIVATE LIMITED becomes super important — ensuring every layer, sheet, and component performs under real-world stress.

Some reasons why insulation is still crucial:

1. Protection Against Electrical Faults

- Insulation prevents short circuits between windings.

- Protects against sudden voltage spikes.

- Helps maintain a stable electromagnetic enviornment inside the transformer.

2. Improved Thermal Resistance

Transformers naturally heat up. If insulation isn’t good quality, that heat breaks down materials fast.

Specialized components like Densified laminated wood are designed to handle high-temperature environments without losing strength or shape.

3. Longer Life & Fewer Failures

Proper insulation isn’t just safety — it’s longevity.

A well-insulated transformer lasts 20–30% longer and reduces the risk of costly downtimes.

The Most Important Transformer Insulation Components

Modern transformer design uses a mix of mechanical and insulation materials. And companies like KE Core Electric provide these in precision-engineered forms.

Here are some of the crucial components used across the power industry:

1. Pre-pressboard & Oil-Compatible Components

Materials like Pre-compress pressboard play a huge role in structural stability.

They resist pressure, absorb oil well, and maintain dimensional strength even after years of operation.

2. High-Performance Laminated Wood

Specialized Densified laminated wood is essential in load-bearing sections such as:

- Clamping rings

- Support blocks

- Lead exits

- Various bracing structures

It combines mechanical strength with excellent insulation, giving transformers both rigidity and protection.

3. Transformer Oil Ducts & Spacers

These parts ensure proper cooling by creating oil channels inside the windings.

Even a small variation in size can cause overheating issues — which is why precision manufacturing is non-negotiable.

The Role of Transformer Parts in Overall Performance

While each component may look small, the combined effect decides how safe, efficient and long-lasting a transformer becomes.

Let’s explore the signifcance of these Transformer Parts:

1. Mechanical Support

Strong insulation materials prevent wobbling or shifting during faults or high-load conditions.

2. Electrical Protection

Without proper insulation between windings, the entire transformer becomes a risk.

3. Heat Dissipation

The right structural design ensures oil flow, reducing hotspots and extending lifespan.

4. Consistency & Reliability

Quality parts eliminate the small inconsistencies that often lead to failures over time.

With decades of expertise, KE Core Electric has become known for producing reliable, standard-compliant parts that power utilities depend on.

How Modern Specialists Are Changing Transformer Manufacturing

The expectations from transformers today are far more demanding than 10–15 years ago. Renewable energy systems, higher peak loads, and increasingly complex grids have made insulation even more important.

This is exactly why Transformer Insulation Parts Specialists are playing a bigger and more crucial role than ever before.

Here’s what has changed in recent years:

A. Greater Precision in Materials

Manufacturers now use advanced machinery to design precise, custom-fit insulation parts.

B. Better Quality Control

Every board, sheet, and wooden block goes through heat testing, compression testing and electrical resistance checks.

C. Environment-Friendly Materials

Sustainable and recyclable insulation materials are now being adopted widely.

D. Custom Designs

Utilities often need transformer parts tailored to their unique network conditions.

Specialists now provide custom-engineered solutions instead of one-size-fits-all.

Why Companies Trust KE Core Electric

Across India and beyond, many companies place their trust in KE CORE ELECTRIC PRIVATE LIMITED for transformer insulation needs.

Reasons include:

- Strong manufacturing capability

- Strict quality benchmarks

- Experience working with global standards

- Customized engineering solutions

- Long-term commitment to reliability

This is why KE Core Electric has grown into a dependable partner for many power utilities and transformer manufacturers.

Conclusion

Transformer technology may look simple from the outside, but inside every unit lies a world of carefully crafted insulation parts, boards, and mechanical supports. These components decide the reliability, life, and performance of every transformer in operation today.

Materials like Densified laminated wood and Pre-compress pressboard may seem small, but they are essential pieces of engineering excellence. And thanks to dedicated specialists and trusted companies like KE Core Electric, the power sector continues to grow stronger, safer, and more dependable day by day.

If you need transformer insulation solutions or want to understand more, reaching out to the experts is always a smart step toward better, safer power systems.

Contact Details

Email: sales@kecoreelectric.com

Office: A-113 & A-114, Mandideep Industrial Area, Raisen District, Madhya Pradesh – 462046, India

Phone: +91 9425012560

Website: https://kecoreelectric.com/

Comments

Post a Comment