The Growing Role of Densified Laminated Wood in Modern Transformer Manufacturing

Transformers have always been one of the backbone elements of power distribution systems, but what’s changing now is how they’re built. The materials, the techniques, and the technology behind the insulation and components are moving fast toward innovation — and one of the front runners in this evolution is KE Core Electric, a name becoming increasingly familiar in the transformer industry.

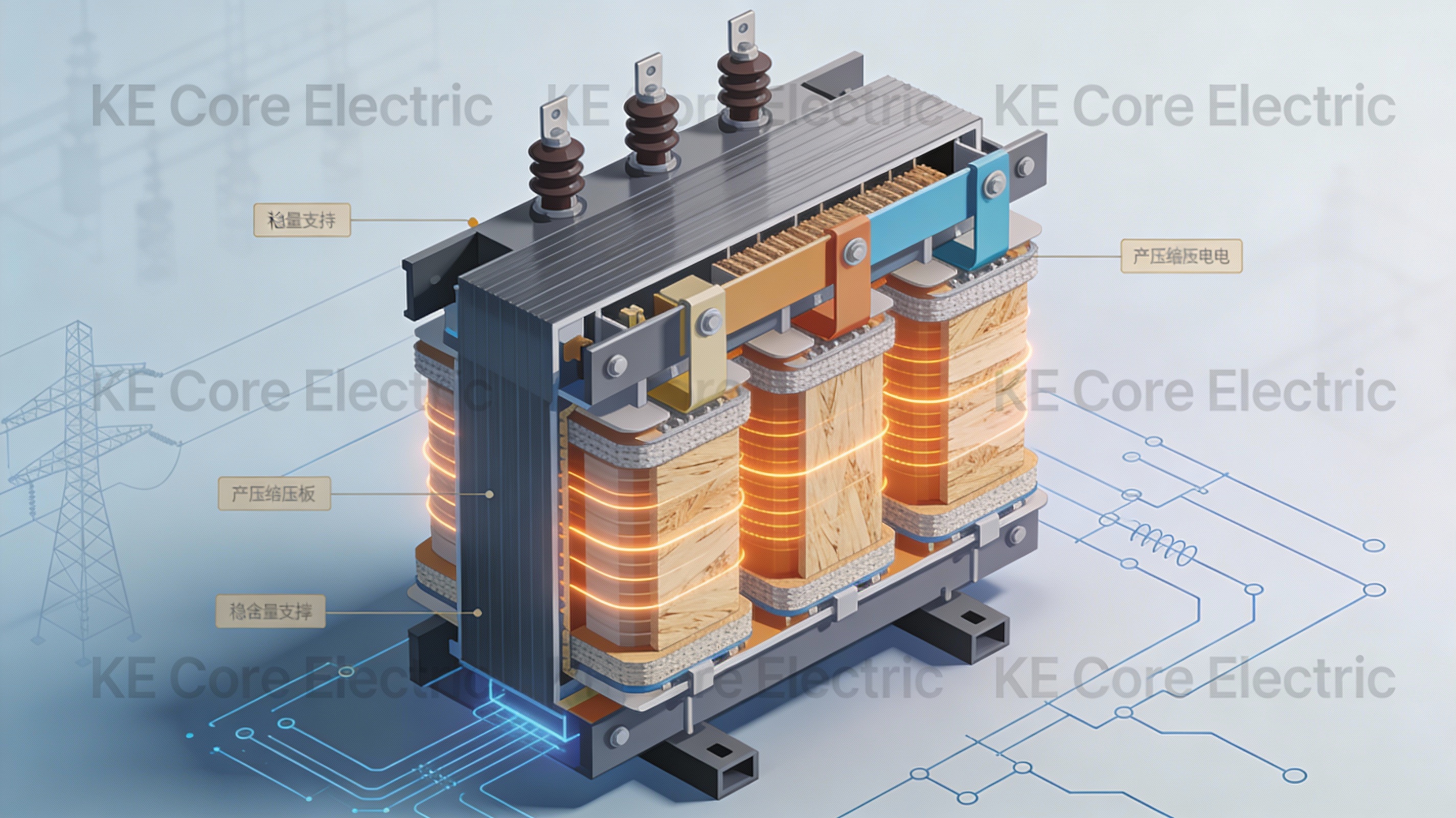

In this article, we’ll explore the advancements in materials like Densified laminated wood, Pre-compress pressboard, and other specialized elements that make up the new generation of power transformer parts. From manufacturing insights to the science of insulation, we’ll unpack how these innovations are shaping long-term performance in an industry that never stops humming.

Understanding the Material: Why Laminated Wood Matters

For decades, transformer makers have relied on wooden and cellulose-based materials for insulation and support. But traditional wood often struggled under extreme heat and mechanical tension.

That’s where Densified laminated wood comes in. The material is engineered under high pressure and temperature, producing a dense, stable structure that can handle enormous mechanical stress. Unlike normal timber, this modified wood maintains its strength even in moist or oil-immersed environments — an essential property for power transformers that must perform under stressful thermal cycles.

As KE Core Electric highlights, this material provides a perfect balance between durability and workability. Components made from it can be machined precisely without compromising insulation quality — a big jump forward for manufacturers aiming for both reliability and operational safety.

The Science Behind Pre-Compress Pressboard

Just as important as structural materials is insulation. Transformers generate a lot of heat during operation, and managing that energy safely is critical. Pre-compress pressboard serves precisely this function.

Manufactured from specially treated cellulose fibers, pre-compressed pressboards are used to insulate conductors and structural parts of both distribution and power transformers. The compression process enhances mechanical strength and dielectric properties — meaning it resists electrical breakdown even under severe load conditions.

A key advantage of using pressboard insulation lies in the control of oil flow within transformer windings. It promotes uniform cooling, which significantly reduces localized heating or “hot spots” that can degrade insulation over time.

In the workshops of companies like KE Core Electric, engineers invest heavily in developing insulation solutions that not only meet international standards but also exceed real-world performance expectations.

The Backbone of Efficiency: Transformer Insulation and Assembly

Without proper Transformer insulation, even the most advanced designs would fail quickly. Insulation ensures that different voltage levels remain separated, prevents arcs, and controls heat dissipation.

In today’s design landscape, multi-layered insulation platforms are being developed with precise thickness variations to fine-tune thermal resistance. The materials used — a hybrid mix of pressboard, kraft paper, laminated wood, and synthetic epoxy composites — are being manufactured and tested in facilities like those at KE Core Electric, ensuring each piece fits tightly into the broader transformer ecosystem.

One of the fascinating parts of modern insulation design is modularity. Instead of a one-size-fits-all structure, manufacturers now produce custom insulation sets tailored for different voltage classes, oil types, or cooling mechanisms. It’s a quieter kind of revolution in transformer tech — but a powerful one nonetheless.

Understanding Transformer Components in 2026

When we examine Transformer Components, it becomes clear that the entire system functions like a living organism. Each piece — from core clamps and tie rods to oil duct spacers and tap changers — must coordinate perfectly to sustain efficient power transformation.

Below are a few critical component categories worth noting:

-

Core and clamping systems: These ensure magnetic flux remains stable and tightly controlled.

-

Winding supports and insulation spacers: Built from densified wood and pressboard, they hold windings in place during magnetic vibration cycles.

-

Cooling ducts and barriers: These influence oil flow patterns, directly affecting transformer lifespan.

-

Mechanical hardware: Bolts, studs, fasteners — each treated or coated to resist oil and heat.

Every transformer has its own “pulse,” depending on its size, load, and operational environment. The component selection process, as practiced by experts at KE Core Electric, is much like fine-tuning a musical instrument: one wrong note and performance falters.

Maintaining a Reliable Transformer Parts Stock

With global energy demand and rapid power grid expansion, having a ready Transformer Parts Stock has become essential for maintenance teams and manufacturers alike. Shortages or mismatched parts can cause extended downtime, something modern utilities absolutely can’t afford.

Companies like KE Core Electric emphasize an agile, quality-controlled supply chain that combines manufacturing capacity with timely delivery. Stocking key insulation components, fasteners, laminated wood structures, and pressboard spacers means contractors can respond fast to service requirements.

This is especially valuable when transformers require on-site repairs in remote or high-demand regions — the right inventory can make or break service continuity.

How Power Transformer Parts Are Shaping Tomorrow

Let’s talk about Power Transformer Parts. The core, windings, insulation, and accessories all contribute to one goal: reliable, long-lasting performance.

The future of these components leans toward more sustainable sourcing — for instance, cellulose derived from eco-friendly processes or wood laminated using lower-carbon adhesives. These innovations, while subtle, carry big long-term implications for transformer sustainability.

Another emerging trend is digital tracking and data tagging of each part during manufacturing. With traceability, engineers can diagnose field issues more efficiently, referencing precise batch and material properties. It’s like having a “digital DNA” for each transformer.

Innovation Is Electrical, but the Passion Is Human

At the end of the day, all technological innovation still depends on human curiosity and craftsmanship. Every component, whether it’s a precisely milled piece of densified wood or a chemical-treated pressboard sheet, traces back to engineers and technicians who want to build better, safer systems.

KE Core Electric stands among those pushing for that blend of high-tech precision and human passion. Their research and focus on material performance highlight a future where transformer longevity improves without sacrificing environmental care.

Conclusion

Transformers are the silent workhorses of industrial and urban electrification. What’s fascinating is how quietly groundbreaking their manufacturing processes have become. From Densified laminated wood to Pre-compress pressboard, the choice of materials now defines efficiency as much as design itself.

And as companies like KE Core Electric continue refining the balance of science, craftsmanship, and supply reliability, it’s clear that the power transmission world is moving not just toward higher voltages — but toward smarter, stronger, and more sustainable systems, one part at a time.

Contact Details

Email: sales@kecoreelectric.com

Office: A-113 & A-114, Mandideep Industrial Area, Raisen District, Madhya Pradesh – 462046, India

Phone: +91 9425012560

Website: https://kecoreelectric.com/

Comments

Post a Comment